concrete reinforcing steel institute manual of standard practice

The Concrete Reinforcing Steel Institute (CRSI) is a leading authority in the construction industry, providing technical guidance and resources for reinforced concrete design and construction.

1.1 Overview of CRSI and Its Role in the Construction Industry

The Concrete Reinforcing Steel Institute (CRSI) is a technical institute and standards-developing organization, serving as the authoritative resource for steel-reinforced concrete. It provides education, technical guidance, and resources to support the design and construction of reinforced concrete structures, ensuring adherence to best practices and industry standards.

1.2 Importance of the Manual of Standard Practice

The Manual of Standard Practice is a comprehensive guide offering detailed specifications, design standards, and construction practices for reinforced concrete. It ensures consistency, quality, and safety in projects, providing engineers and contractors with essential resources to meet industry requirements and best practices effectively.

Scope and Structure of the Manual

The manual provides a detailed framework for reinforced concrete design, covering material specifications, construction practices, and quality control, organized into clear sections for easy reference and application.

2.1 Key Sections and Chapters in the Manual

The manual is structured into key sections, including material specifications, design considerations, construction practices, testing, and sustainability. Each chapter provides in-depth guidance, ensuring comprehensive coverage of reinforced concrete principles and applications, updated regularly to reflect industry advancements and best practices for optimal construction outcomes and durability.

2.2 Updates and Revisions in Recent Editions

Recent editions of the manual include updated ASTM standards, enhanced sustainability guidelines, and new sections on digital design tools like BIM. Revisions address emerging technologies, improved testing methods, and corrosion protection strategies, ensuring the manual remains a cutting-edge resource for reinforced concrete professionals and aligns with modern industry demands and advancements.

Material Specifications and Standards

The CRSI Manual outlines ASTM standards for reinforcing steel, detailing grade requirements, mechanical properties, and chemical composition to ensure material quality and performance in concrete structures.

3.1 ASTM Standards for Reinforcing Steel

The ASTM standards provide detailed specifications for reinforcing steel, including chemical composition and mechanical properties. These standards ensure consistency and quality, guiding manufacturers and engineers in producing and selecting suitable steel for concrete reinforcement, as outlined in the CRSI manual.

3.2 Grade Requirements and Mechanical Properties

Grade requirements for reinforcing steel ensure adherence to tensile strength, yield strength, and elongation standards. Mechanical properties are critical for structural integrity, determining the steel’s suitability for various applications. These specifications are detailed in the CRSI manual to guarantee optimal performance in reinforced concrete construction.

3.4 Fabrication and Tolerances

Fabrication and tolerances ensure reinforcing steel meets precise standards for structural integrity. The CRSI manual outlines specific guidelines for cutting, bending, and assembling steel reinforcement. Tolerances are defined to accommodate fabrication variations, ensuring compliance with design specifications and maintaining the safety and durability of reinforced concrete structures.

Design Considerations for Reinforced Concrete

Design considerations involve load calculations, structural analysis, and reinforcement detailing. Proper placement and cover requirements ensure durability and safety in concrete structures.

4.1 Load Calculations and Structural Analysis

Load calculations involve determining dead, live, and environmental loads. Structural analysis ensures that reinforced concrete elements, like beams and columns, can withstand stresses and strains. Accurate calculations are critical for safety and durability, adhering to CRSI standards for optimal design outcomes.

4.2 Reinforcement Detailing and Placement

Reinforcement detailing ensures proper placement of steel bars, including spacing, cover, and anchorage. Correct detailing prevents structural failures and ensures compliance with design specifications. CRSI guidelines emphasize precise placement techniques for optimal strength and durability in reinforced concrete structures, minimizing defects and enhancing overall performance.

4.3 Concrete Cover and Spacing Requirements

Concrete cover protects reinforcing steel from environmental factors, ensuring durability. CRSI specifies minimum cover depths and spacing to prevent corrosion and maintain structural integrity. Proper spacing between bars allows for even concrete flow, preventing defects and ensuring compliance with industry standards for safety and longevity in reinforced concrete structures.

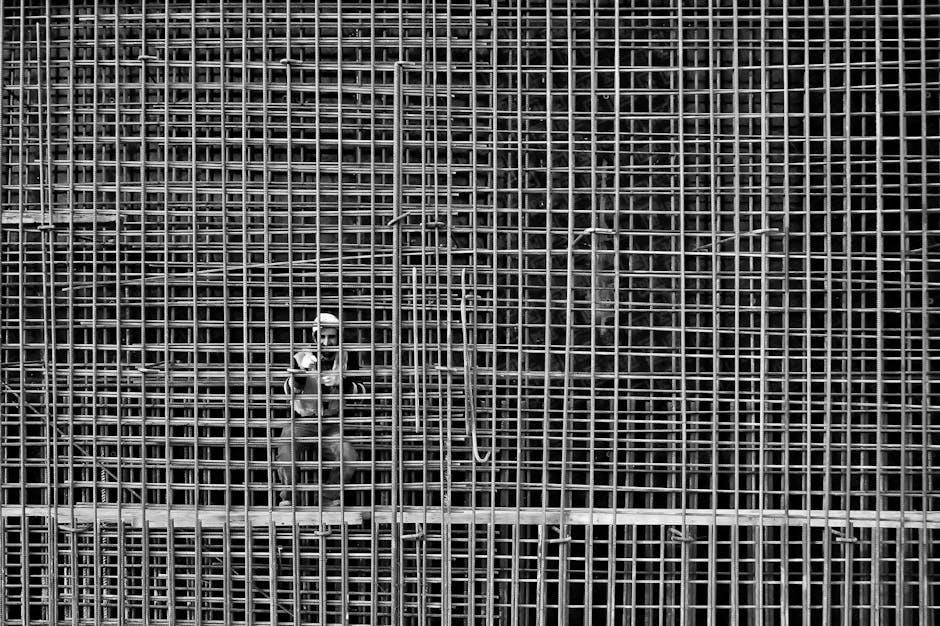

Construction Practices and Field Guidelines

CRSI provides comprehensive guidelines for handling, installing, and quality control of reinforcing steel. Adherence to safety protocols, proper techniques, and compliance with standards ensure durable and structurally sound concrete construction, minimizing defects and enhancing overall project integrity.

5.1 Handling and Storage of Reinforcing Steel

CRSI guidelines emphasize proper handling and storage techniques to prevent damage and ensure safety. Reinforcing steel should be stored in a dry, flat area, protected from corrosion, and handled with appropriate equipment to avoid bending or distortion, ensuring structural integrity and compliance with quality standards throughout construction.

5.2 Installation Techniques and Safety Precautions

CRSI recommends precise installation techniques to ensure structural integrity. Safety measures include wearing protective gear, securing the site, and using proper lifting equipment. Steel reinforcement must be accurately placed according to design specifications to prevent defects, ensuring durability and compliance with safety standards during construction.

5.3 Inspection and Quality Control Measures

CRSI emphasizes rigorous inspection and quality control to maintain high standards. This includes verifying steel placement, concrete cover, and spacing. Regular checks ensure compliance with specifications, while documentation and reporting are essential for traceability and accountability, ensuring the final structure meets safety and durability requirements.

Testing and Verification Procedures

Testing and verification ensure reinforced concrete structures meet quality and safety standards. Non-destructive methods, material sampling, and thorough documentation are critical for compliance and reliability.

6.1 Non-Destructive Testing Methods

Non-destructive testing methods, such as ultrasonic testing and magnetic particle testing, are employed to evaluate reinforcing steel and concrete without causing damage. These techniques help detect flaws, ensuring structural integrity and compliance with CRSI standards, while maintaining the lifespan of reinforced concrete structures.

6.2 Sampling and Testing of Concrete and Steel

Sampling and testing of concrete and steel involve collecting representative specimens to assess material properties. Tests include chemical composition, mechanical strength, and concrete compressive strength. These procedures ensure compliance with ASTM standards and CRSI guidelines, verifying material quality and structural integrity for safe and durable construction.

6.3 Documentation and Reporting Requirements

Proper documentation ensures transparency and accountability in construction projects. Detailed records of test results, inspection logs, and compliance reports are essential. Reports must adhere to CRSI guidelines, documenting material quality, structural integrity, and adherence to ASTM standards, ensuring all specifications are met for safe and durable construction outcomes.

Applications of Reinforced Concrete in Modern Construction

Reinforced concrete is widely used in modern construction for buildings, bridges, and industrial structures, offering strength, durability, and cost-effectiveness, making it a versatile material for diverse projects.

7.1 Buildings and High-Rise Structures

Reinforced concrete is integral to modern building construction, particularly in high-rise structures, where its strength, durability, and cost-effectiveness meet the demands of urban development and architectural innovation, ensuring safety and sustainability in large-scale projects.

7;2 Bridges and Highway Infrastructure

Reinforced concrete is essential for constructing durable bridges and highway infrastructure, offering high strength and resistance to environmental factors. CRSI guidelines ensure longevity, safety, and minimal maintenance, making it a preferred choice for transportation systems requiring long-term reliability and structural integrity in demanding conditions.

7.3 Industrial and Specialized Structures

Reinforced concrete is integral to industrial and specialized structures, such as warehouses, power plants, and containment facilities. CRSI standards ensure these structures meet stringent safety and performance demands, supporting heavy loads and withstanding harsh operational conditions while maintaining long-term durability and structural integrity.

Durability and Maintenance of Reinforced Concrete Structures

Durability and maintenance are crucial for extending the lifespan of reinforced concrete structures, ensuring safety and performance under various environmental and mechanical stresses over time.

8.1 Factors Affecting Durability

Environmental conditions, material quality, and construction practices significantly influence the durability of reinforced concrete structures. Corrosion of steel, chemical attacks, and poor workmanship can compromise longevity. Proper design, high-quality materials, and effective maintenance are essential to mitigate these factors and ensure long-term structural integrity and performance.

8.2 Maintenance and Repair Techniques

Regular inspections, timely repairs, and protective coatings are crucial for maintaining reinforced concrete structures. Addressing cracks, spalling, and corrosion early prevents further damage. Techniques include epoxy injections, patching, and cathodic protection to restore structural integrity and extend service life, ensuring safety and reliability of the structure over time.

8.3 Corrosion Protection and Prevention

Corrosion protection is essential for extending the lifespan of reinforced concrete structures. Techniques include applying protective coatings, using corrosion-resistant steel, and implementing cathodic protection systems. Proper concrete cover and quality control during construction also play a vital role in preventing corrosion and ensuring the durability of the reinforcing steel.

Sustainability and Environmental Considerations

Sustainability is a key focus in modern construction, with practices like green building certifications and reducing material waste. The manual emphasizes eco-friendly methods to minimize environmental impact.

9.1 Green Building Practices and LEED Certification

Green building practices, aligned with LEED certification, emphasize sustainable materials and energy efficiency. CRSI’s manual provides guidelines for using reinforcing steel in eco-friendly projects, promoting reduced environmental impact while maintaining structural integrity and durability in construction.

9.2 Reducing Environmental Impact Through Design

Design strategies can significantly minimize environmental impact by optimizing material use and reducing waste. The CRSI manual emphasizes sustainable practices, such as efficient steel reinforcement detailing and waste reduction techniques, to align with eco-friendly construction methods and promote environmentally responsible building practices.

9.3 Recycling and Reuse of Reinforcing Steel

Recycling and reusing reinforcing steel are critical for sustainability. The CRSI manual highlights methods to salvage and repurpose steel from demolished structures, reducing the need for new production and conserving resources, thus promoting a circular economy in the construction industry.

Case Studies and Real-World Applications

Real-world projects highlight the practical application of CRSI standards, showcasing successful implementations and lessons learned, inspiring innovation and adherence to best practices in reinforced concrete construction.

10.1 Successful Projects Using CRSI Guidelines

Notable projects adhering to CRSI guidelines demonstrate enhanced durability and structural integrity. These include high-performance bridges and sustainable buildings, where adherence to CRSI standards ensured optimal material use, improved safety, and compliance with modern engineering practices, setting benchmarks for future developments in reinforced concrete construction and design.

10.2 Lessons Learned and Best Practices

CRSI’s manual highlights key lessons from successful projects, emphasizing precise reinforcement detailing, strict quality control, and adherence to updated standards. These best practices enhance project efficiency, reduce errors, and ensure long-term structural reliability, serving as invaluable insights for engineers and contractors in the field of reinforced concrete construction.

Training and Certification Programs

CRSI offers certification programs, workshops, and educational resources to enhance expertise in reinforced concrete design and construction, ensuring professionals stay updated with industry standards and best practices.

11.1 CRSI-Certified Professionals and Their Roles

CRSI-certified professionals are experts in reinforced concrete design and construction. Their roles include ensuring compliance with industry standards, providing technical guidance, and promoting best practices. They contribute to project quality and safety, acting as key resources for contractors, engineers, and architects.

11.2 Educational Resources and Workshops

CRSI offers comprehensive educational resources and workshops to enhance industry knowledge. These programs cover design, construction, and sustainability practices, providing professionals with practical skills and updates on standards. Workshops foster collaboration and continuous learning, ensuring the industry remains innovative and aligned with best practices.

Future Trends and Innovations

CRSI is at the forefront of advancing reinforced concrete technology. Future trends include sustainable materials, digital design tools, and innovative construction techniques, driving efficiency and environmental responsibility.

12.1 Advances in Reinforcing Steel Technology

Advances in reinforcing steel technology include high-strength, corrosion-resistant materials and sustainable production methods. These innovations enhance durability, reduce maintenance, and align with green building practices, supported by CRSI’s research and standards.

12.2 Emerging Construction Techniques

Emerging techniques include precast concrete systems, self-healing concrete, and advanced composite materials. These innovations improve efficiency, sustainability, and durability, aligning with modern design and environmental standards, as highlighted in CRSI’s resources for cutting-edge construction practices.

12.3 Digitalization and BIM in Reinforced Concrete Design

Digitalization and Building Information Modeling (BIM) are revolutionizing reinforced concrete design. BIM enables precise modeling, enhancing collaboration and accuracy. CRSI supports these advancements, offering resources for integrating BIM in design processes, improving project efficiency, and reducing errors, as outlined in their manual for modern construction practices.

The CRSI Manual of Standard Practice remains a cornerstone for reinforced concrete construction, ensuring adherence to best practices and fostering innovation in the industry.

13.1 The Evolving Role of CRSI in the Industry

CRSI continues to evolve as a trusted leader, advancing standards and practices in reinforced concrete construction. By addressing emerging challenges and promoting innovation, CRSI remains instrumental in shaping the future of the construction industry through education, technical resources, and a commitment to sustainability and excellence.

13.2 Encouraging Continuous Improvement and Adoption

CRSI actively promotes continuous improvement by providing educational resources, training programs, and updated standards. By fostering collaboration and innovation, CRSI encourages the adoption of best practices, ensuring the construction industry remains at the forefront of sustainable and resilient design, ultimately driving progress in reinforced concrete construction and related fields.