manual lavadora general electric modelos

General Electric offers a wide range of washing machine models designed for efficiency and durability. Their manuals provide essential installation, operation, and maintenance instructions, ensuring optimal performance and troubleshooting guidance. Available online, these guides help users maximize their appliance’s potential.

Overview of Popular GE Washing Machine Models

GE offers a variety of washing machine models, each designed to meet specific needs. Popular models include the GUD24GSSMWW, known for its advanced dispensing system and high-efficiency performance, and the GTW465ASNWW, which features a large capacity and intuitive controls. The LV1135 model is praised for its durability and reliable operation. Many GE models come with energy-saving technologies and multiple wash cycles, catering to both residential and commercial use. Manuals for these models are readily available online, providing detailed instructions for installation, operation, and troubleshooting. These models highlight GE’s commitment to innovation, efficiency, and user-friendly design, making them top choices for homeowners seeking dependable appliances.

Importance of Using the Correct Manual for Your Model

Using the correct manual for your GE washing machine model is crucial for proper installation, operation, and maintenance. Each model has unique features and requirements, and the manual provides specific instructions tailored to your appliance. Incorrect usage can lead to malfunctions, safety hazards, or voiding the warranty. Manuals are available online in multiple languages, including Spanish and English, ensuring accessibility for all users. They cover essential topics like detergent usage, cycle selection, and troubleshooting. Referencing the correct manual helps prevent errors, ensures optimal performance, and extends the lifespan of your washing machine. Always verify your model number to download the accurate guide for your specific appliance.

Installation and Setup Instructions

Proper installation of your GE washing machine is essential to prevent damage and ensure safety. Always follow model-specific instructions to avoid malfunctions and ensure efficient operation.

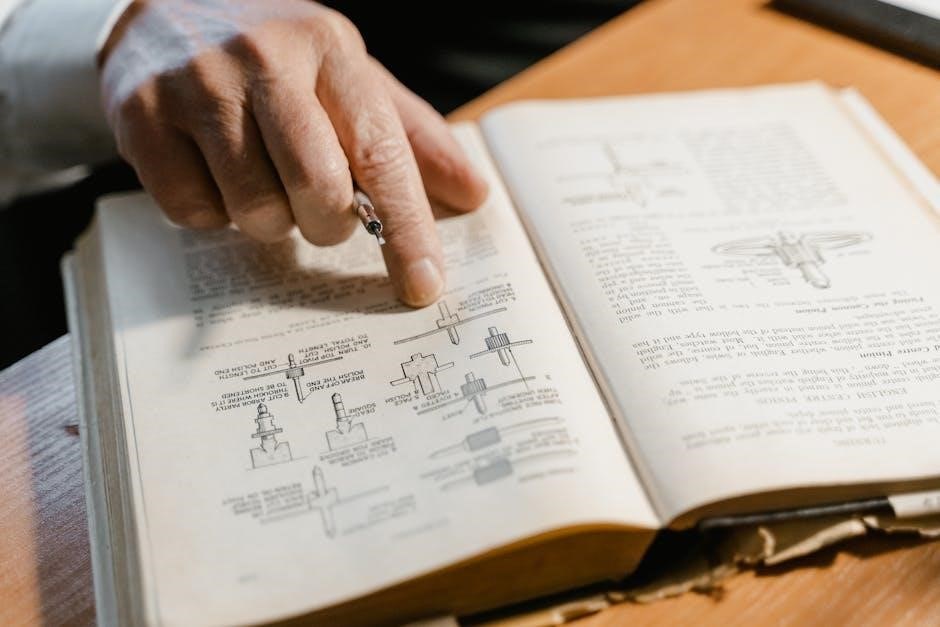

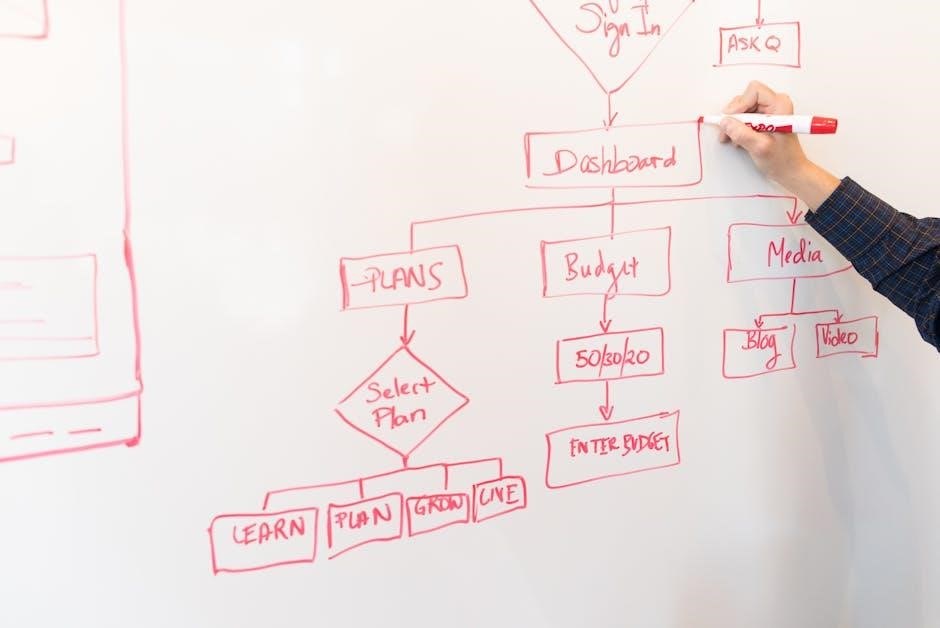

Step-by-Step Guide for Installing Your GE Washing Machine

Unpack the washing machine and ensure all components are included. Inspect for damage and report any issues to avoid installation problems. Level the machine using adjustable feet to prevent vibration. Connect water supply lines to the correct hot and cold water inlets. Ensure electrical connections are secure and meet local codes. Install the drain hose properly, avoiding kinks or blockages. Test the machine by running a short cycle without detergent to check for leaks or noise. Refer to the manual for specific model requirements, such as additional accessories or settings. Proper installation ensures safety, efficiency, and optimal performance of your GE washing machine.

Connecting Electrical and Water Supply Lines

Connecting your GE washing machine requires careful attention to electrical and water supply lines. Ensure the washing machine is unplugged before starting. Connect the electrical cord to a properly grounded 120V outlet, avoiding extension cords. For water supply, attach the hot and cold water hoses to the respective inlet valves on the machine, ensuring they are securely tightened. Use Teflon tape to prevent leaks. If your home has high water pressure, consider installing a water hammer arrestor. Refer to your model’s manual for specific instructions, as some models may have additional requirements. Proper connections ensure safe and efficient operation of your washing machine.

Operating the Washing Machine

Operating your GE washing machine involves selecting the right wash cycle via the control panel, using HE detergent, and following guidelines for optimal cleaning efficiency.

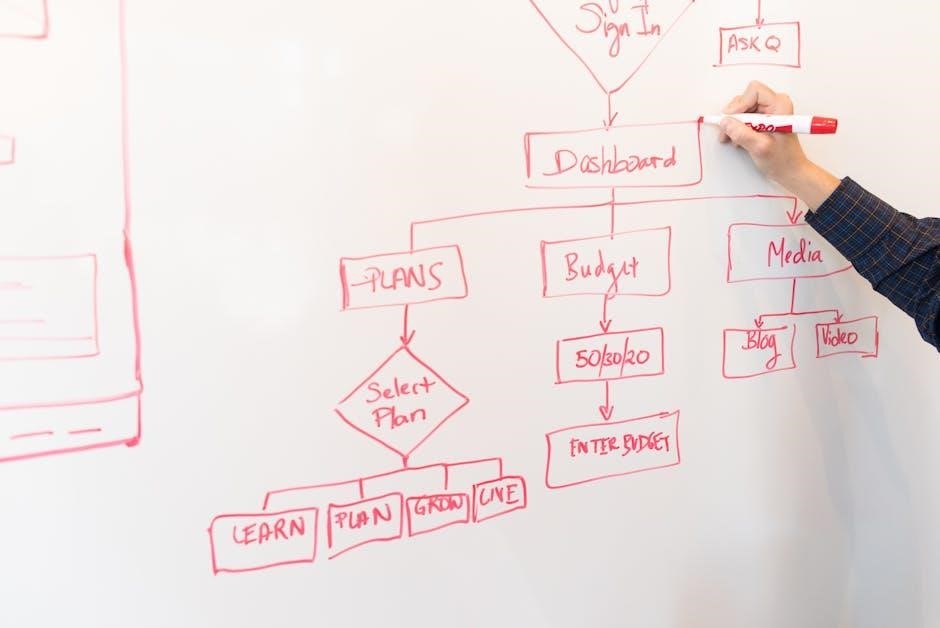

Understanding Control Panels and Wash Cycles

GE washing machines feature intuitive control panels with options for selecting wash cycles, water temperature, and spin speed. Common cycles include Normal, Heavy Duty, and Delicate. The timer allows precise control over wash and rinse times. Specialized settings like Deep Fill and Sanitize ensure tailored cleaning for specific fabric types. Dispensers for detergent, bleach, and fabric softener are clearly labeled, guiding users to add the correct amounts. The control panel also provides status updates during operation. Referencing the manual ensures proper use of advanced features, optimizing cleaning efficiency and fabric care. Understanding these controls enhances user experience and prolongs appliance lifespan.

Using Detergent and Fabric Softener Dispensers

GE washing machines feature convenient detergent and fabric softener dispensers to streamline the laundry process. The detergent dispenser typically has three compartments: one for pre-wash, main wash, and fabric softener. For optimal performance, use high-efficiency (HE) detergent, as recommended in the manual. Avoid overfilling compartments, as this can lead to residue buildup. Fabric softener should be added to the designated dispenser, ensuring it’s released during the rinse cycle. Always refer to your model’s manual for specific instructions, as dispenser designs may vary. Proper use of these dispensers ensures effective cleaning, prevents clogging, and maintains your washer’s efficiency over time.

Maintenance and Troubleshooting

Regular maintenance ensures your GE washing machine runs efficiently. Clean filters, check for blockages, and run cleaning cycles. Troubleshooting common issues like error codes or leaks.

Cleaning the Washing Machine and Filters

Regular cleaning of your GE washing machine and its filters is essential for optimal performance. The filter, often located beneath the agitator or at the pump, should be cleaned periodically to remove debris. Run a cleaning cycle with a washer cleaner or vinegar to eliminate odors and residue. Check the detergent dispenser for buildup and wipe it clean. For models like the GUD24GSSMWW, ensure the chlorine compartment is emptied after use. Leave the lid open after cycles to dry the interior. Refer to your specific model’s manual for detailed instructions. Regular maintenance prevents mold growth and ensures fresh, clean laundry every time.

Common Issues and Solutions for GE Models

GE washing machines may encounter issues like clogged filters, detergent dispenser buildup, or error codes. For clogs, clean the filter regularly, especially after detecting debris. If the dispenser is clogged, soak it in warm water. Error codes often indicate specific problems, such as imbalanced loads or drainage issues. Models like the GUD24GSSMWW may show errors for oversize loads or poor ventilation. Regular cleaning cycles with vinegar or cleaning agents can prevent mold and odors. Always refer to your model’s manual for troubleshooting guidance. Ensuring proper maintenance and addressing issues promptly extends the appliance’s lifespan and performance. Check user manuals for detailed solutions tailored to your specific GE model.

Frequently Asked Questions

Frequently Asked Questions about GE washing machines include troubleshooting tips, detergent recommendations, and warranty details. Manuals and customer support are available online for assistance.

Energy Efficiency and HE Detergent Usage

General Electric washing machines are designed to be energy efficient, with many models earning the ENERGY STAR certification. Using HE (High Efficiency) detergent is recommended, as it produces fewer suds and is specifically designed for low-water washing machines. HE detergent helps maintain your washer’s performance and prevents residue buildup. ENERGY STAR certified models use less water and energy, reducing utility bills and environmental impact. Always check your manual for detergent recommendations, as using the wrong type can affect efficiency. Proper detergent usage ensures optimal cleaning and longevity of your GE washing machine.

Warranty and Customer Support Information

General Electric washing machines come with comprehensive warranties, typically covering parts and labor for up to one year, with extended options available. The motor often has a 10-year warranty. Customers can register their products online for warranty activation and access support resources. GE Appliances provides dedicated customer service through their website, phone, and live chat. Manuals and troubleshooting guides are readily available online to address common issues. For further assistance, users can contact GE’s support team or visit authorized service centers. Warranty details and support options ensure peace of mind and reliable service for GE washing machine owners.

GE washing machine manuals are essential for optimal use, offering detailed guides for installation, operation, and troubleshooting. Additional resources are available online, including FAQs, user forums, and direct customer support, ensuring comprehensive assistance for all models. Visit the official GE Appliances website for the latest manuals and support information.

Where to Find More Information and Manuals Online

General Electric washing machine manuals and additional resources are readily available online. Visit the official GE Appliances website for model-specific guides, troubleshooting tips, and warranty information. Third-party platforms like ManualsLib and ManualsOnline also host a wide range of GE washing machine manuals. For specific models, such as the GE GUD24GSSMWW or GE GTW465ASNWW, search the model number along with “manual” to find detailed instructions. Additionally, user forums and customer support pages provide helpful insights and answers to common questions. Ensure to download manuals from trusted sources to avoid misinformation.